With its HeliBox line of prototype polarizers, Xemed has adopted a unique approach for producing hyperpolarized helium-3 using Spin Exchange Optical Pumping. By enclosing the components inside a pressure vessel, the HeliBox polarizers utilize larger glass cells and higher pressures than would otherwise be possible. The second generation system achieved spin-up rates of 20% per hour on helium quantities as large as 50 STP liters.

HeliBox-Z100, presently begin assembled, is Xemed’s third-generation system for producing large quantities of highly polarized helium-3 using Spin Exchange Optical Pumping. When testing begins in the fall of 2011, we expect industry-leading polarizations and spin-up rates, as well as high reliability, compact size, and low cost.

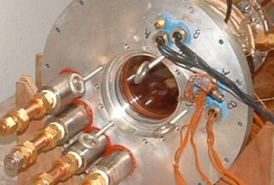

- Technology: The laser system incorporates four diode-bar stacks wavelength-locked to 795nm using an external cavity with a diffraction grating in Littrow configuration yielding a 2.5kW beam with 0.3nm spectral full width and 5 mr divergence. The polarizing cell is a fully blown, monolithic aluminosilicate cell with a blown end window. Optical aberrations introduced by the irregular window are compensated by a custom correction plate.

- Intellectual Property: Xemed has licensed technology from the University of New Hampshire that relate to the spectrally-narrowed laser.

- Portability & Robustness: The HeliBox-Z100 was designed with portability in mind. All components are encased in a protective steel frame optimized for rigidity using finite element analysis. The wheels are on springs. Internally, the laser rides on cushions inside this frame. The glass cell containing the rubidium is fully enclosed with metal and immersed in oil. Even the shipping palette is engineered to minimize shocks and accelerations.

- Automation: All steps of the polarization process, including warm-up, polarize, measure polarization, optimize operating parameters, and cool down, are controlled by an on-board computer interfaced to a National Instruments Compact-RIO controller. Quality parameters and other diagnostics are recorded and logged. The HeliBox-Z100 polarizer can be controlled and diagnosed for problems either locally or remotely through an Ethernet connection.

- Quality: The on-board NMR system is calibrated at its operational frequency using a water standard at reduced field (both B0 and B1). Quality-factor corrections for changes in the coil temperature are included.

- Environment: HeliBox-Z100 is designed to operate in small spaces. At 77.5” tall, it will fit through standard height doors. Its fully enclosed laser path allows for Class 1 operation (no special protections required.) Since essential components are water cooled, fan noise is kept to a minimum.

- Installation: HeliBox-Z100 requires connections for 50A of 208V 3phase electrical power, 10kW of facility chilled water, compressed air, and ethernet. The 33”x66” footprint also includes connections to several cylinders of compressed gas and a tank of liquid nitrogen.

- Service: Xemed provides off-site telephone service and on-site annual service for all HeliBox-Z100 polarizers in the field.